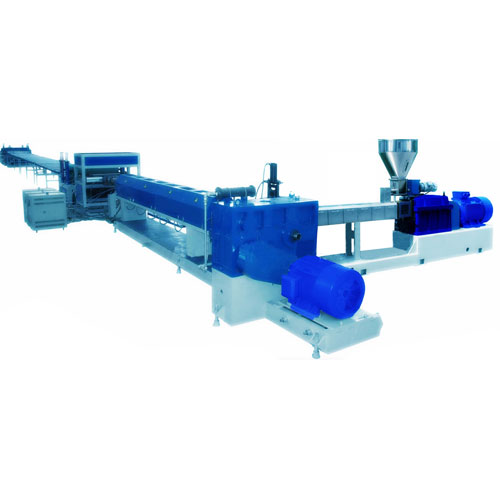

- Product Name: Twin-single Screws Extruder for XPS Foamed Board

- Model NO.: BHSD

-

Product Details: Twin-single Screws Extruder for XPS Foamed Board

I. Technical parameters:

Machine Type |

Screw Diameter (mm) |

L/D | Motor Power (KW) |

Output (m3/d) |

Board Width (mm) |

Board Thickness (mm) |

Total Power (KW) |

Total Weight (Ton) |

Outline Dimension (mm) |

| BHSD- 65/150 |

62.4 | 32 | 55 | >300 | 600/ 900 |

20-100 | 150 | 24 | 40000* 1400*4000 |

| 150 | 40 | 45 | |||||||

| BHSD- 75/160 |

71.2 | 32 | 75 | >400 | 600/ 1200 |

20-100 | 190 | 26 | 40000* 1600*4000 |

| 160 | 40 | 55 | |||||||

| BHSD- 95/200 |

93.6 | 32 | 110 | >600 | 600/ 1200 |

20-180 | 280 | 38 | 50000* 1700*4000 |

| 200 | 40 | 75 |

II. Advantages of Twin/single Screws Extrusion Line for XPS:

- XPS board extruded with low density (28Kg/m3).

- Big output (BHSD-65/150: 250-300/24 m3hr; BHSD-75/160: 350-400/24 m3hr).

- Accurate control of temperature and drive, with high efficiency and low energy consumption.

- Good quality of finished XPS foamed boards (good flatness, excellent closed pore, good honeycomb texture, high compression strength).

- Easy controlling system designed, with less errs happen.

-

Product Images: Twin-single Screws Extruder for XPS Foamed Board